Silver Epoxy Turns Black After an Oxygen Plasma Clean Prior to Wire Bonding – But so What?

Learn more about epoxy bleed from industry expert Tom Green. Here is the abstract of the white paper Silver Epoxy Turns Black After an Oxygen Plasma Clean Prior to Wire Bonding:

“In the early 1970s component manufacturers switched to epoxies for die attach in lieu of a eutectic attach. Resin bleed out was a common problem with these early epoxies and still is today. Resin bleed is difficult to see unless a filtered light source is connected to the microscope. The easiest and most effective manner to clean epoxy resin bleed, and other outgassed organic species, is to expose the assembly to a UV Ozone or an O2 plasma treatment just prior to wire bonding. However, oxygen plasma turns the silver die attach epoxy black. Customers often take offense to this color change and hence O2 plasma cleaning prior to wirebond in large microwave hybrids and for other product types is normally not performed. Argon plasma is used instead.

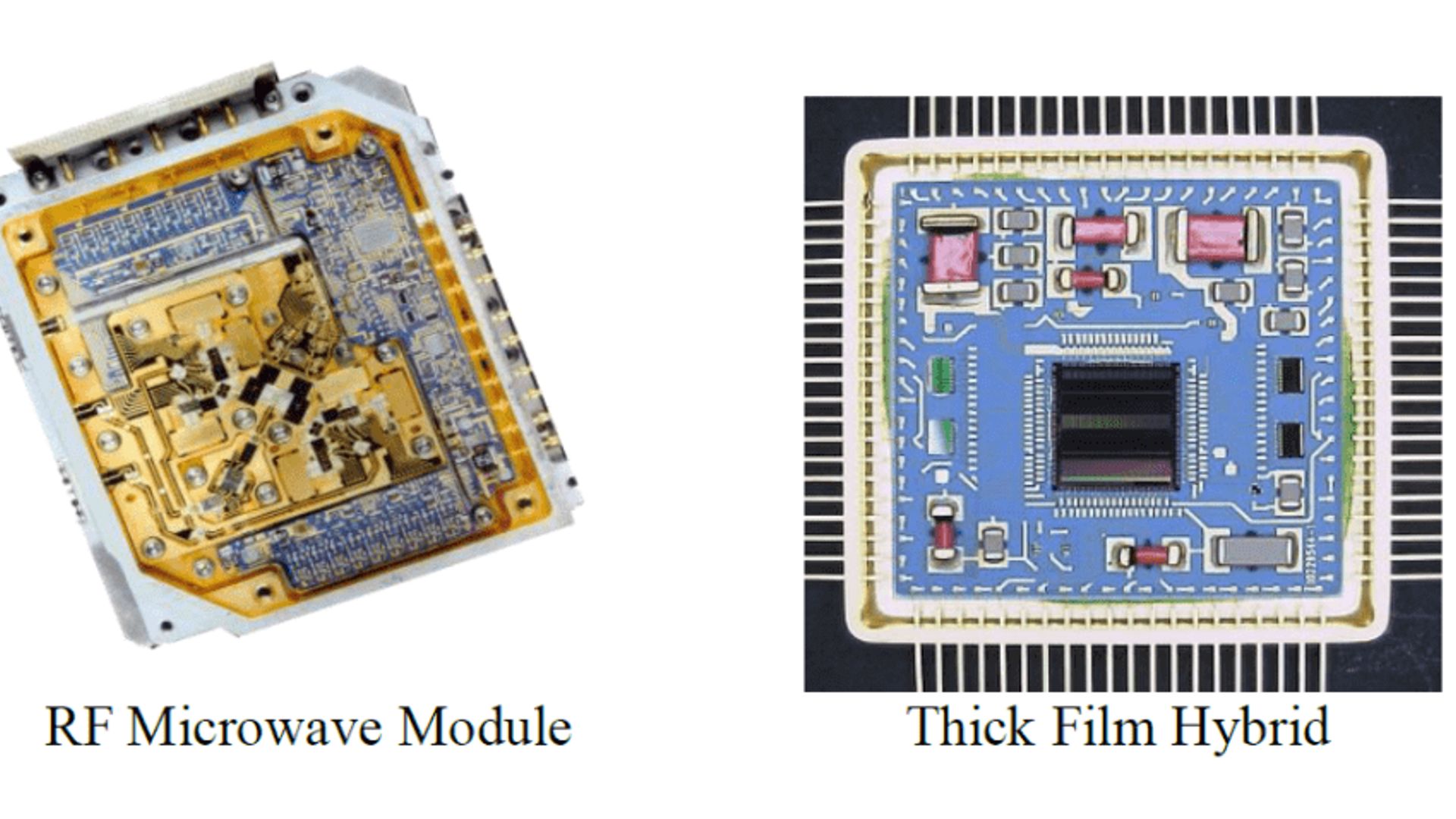

This presentation reviews the chemistry involved in the formation of “black epoxy” and how the silvery epoxy appearance can easily be restored, thereby allowing for a more aggressive clean prior to wirebond. Rework of wire no sticks or multiple wirebond attempts on the same pad is a major concern in the manufacture of large area Hybrids and RF MMIC microwave hybrids and a big contributor to expensive rework cycles. How to effectively clean up resin bleed and deal with the “black epoxy” is the subject of this white paper.”