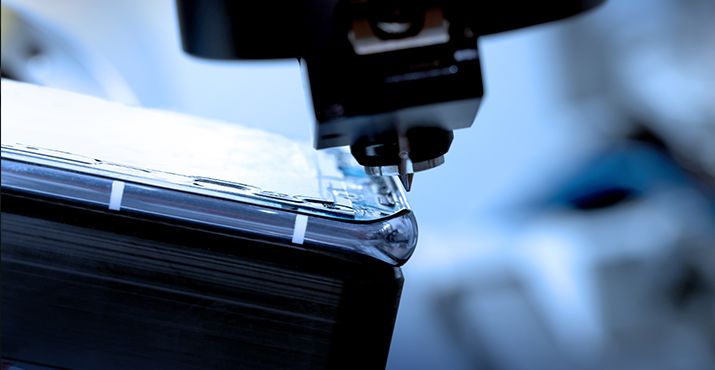

Axxon creates coating systems

Axxon is a leading, global supplier of innovative and production-ready, dispense and conformal coating systems. Expertly designed for to perform in high volume, high mix, and varied and other customized production needs environments.

Manufacturing, design, development, and operations are located in Shenzhen, China.

The factory is backed by worldwide applications and support teams located across SEA, the United States, Mexico, and Europe.

Each region has fully equipped demonstration facilities to properly support the unique requirements of each customer base. with equipment suited to your region.

The product platforms are well established in markets such as Electric Vehicle automotive (traditional and EV), consumer electronics (ie: mobile phones), and semiconductors; working with fluids such as Thermal Interface (TIM), RTV, and Potting, 2K fluids, under-fill and, conformal coating.

There isn’t a fluid we can’t dispense. The factory-based valve team is continually developing new dispense technologies to accommodate the latest fluid demands from under-fill, solder pastes, surface mount adhesives, 2-part fluids, and beyond.

Axxon is your proven and solid partner for any dispensing and conformal coating need.

The right platform for your process

The right platform for your process

Valves for each application