Die bonding solution targets modern photonics manufacturing – building bricks for 5G rollout

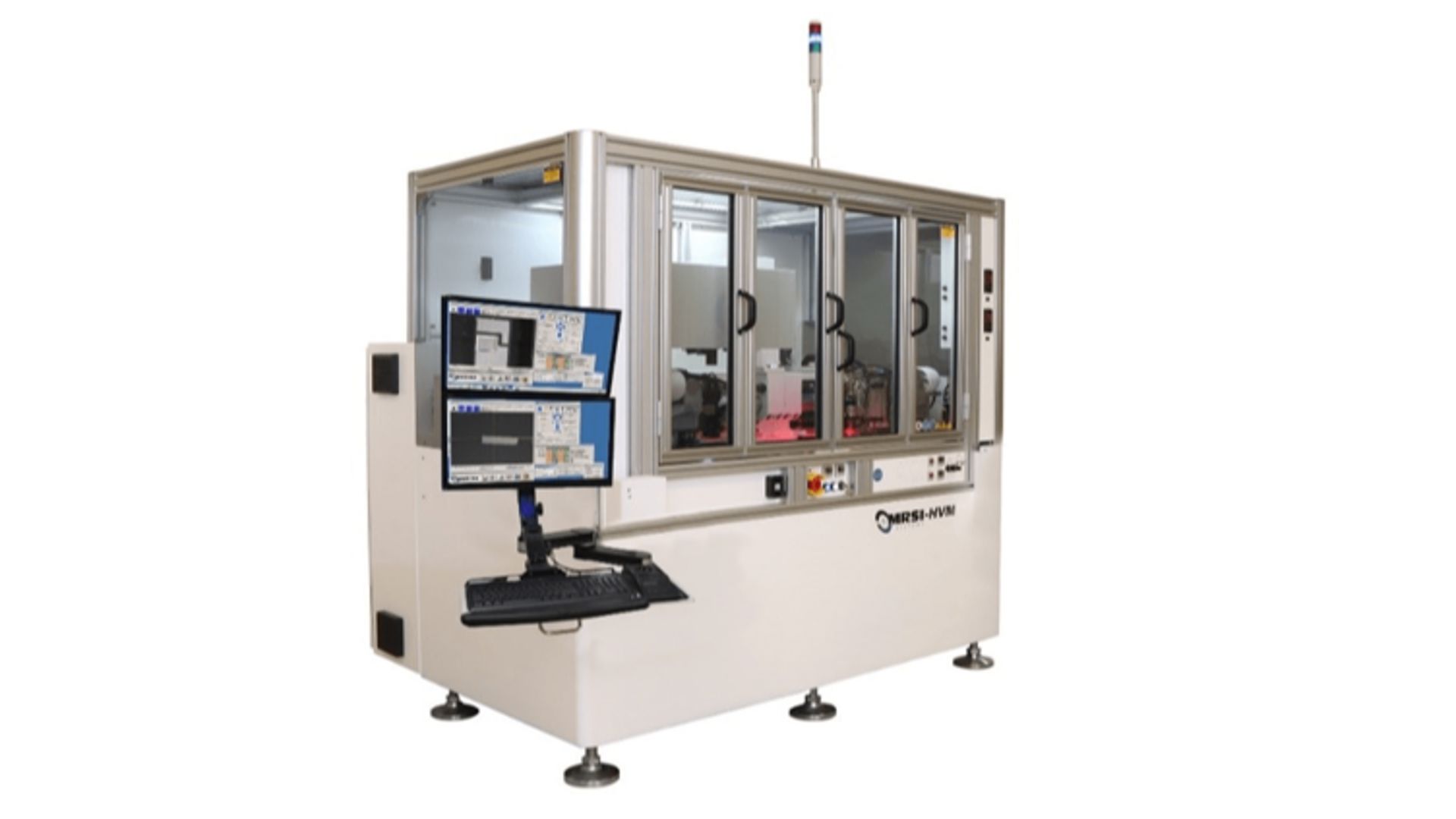

5G continues to drive the needs of the Datacom supply chain which presents challenges to photonic device manufacturers. In this article featured in Laser Focus World, MRSI highlights the high-volume, high-mix nature of optical components required for 5G wireless and 400G+ datacenter and backbone network applications, requiring flexible <±1.5 µm high accuracy die-bonder platforms. Our solution to these challenges includes our MRSI-HVM where our field application results demonstrate less than ±3 µm post-bonding accuracy.

The full article sets out the immediate challenges facing these manufacturers and potential solutions that are working in the field.

Excerpt:

Global 5G deployment and datacenter applications over the next five years are expected to have exponential growth rates.1 This drives the demand for high-performance optical communication devices as one of the most critical building blocks. Specifically, these critical components are supporting 5G wireless fronthaul and the shipments of next-generation Ethernet modules, including 2x200GbE, 4x100GbE, and 400GbE, as well as CWDM/DWDM transceivers.

This major market growth of new high-performance optical devices has generated new requirements, including much-smaller packaging housing, smaller chips/dies with higher density in the package, rapid technology innovation, quick product iterations, higher-volume manufacturing, and at an economical price point. The new requirements are also needed in lidar, AR/VR, and advanced photonic sensors, as well as MEMS and even the highly integrated silicon photonics devices