The power of one

— empowering multi-machine programming with one dataset, one program and one workflowFor years, Mycronic inspection customers have benefitted from a single web-based interface for unified SPI and AOI data. The latest MYPro Create™ software brings the same seamless integration to jet printing, making job creation faster, more intuitive and more stable than ever before.

With this new release, MYPro Create brings a single, intuitive workflow to job creation for Mycronic jet printing, SPI and AOI systems. Future releases will extend these capabilities to pick-and-place machines, resulting in a complete program creation software for all Mycronic machines. To learn more about how the new unified programming software contributes to customers’ productivity, we spoke with Software Architect Milos Homola.

One dataset for all machine programs

Current jet printer users will experience the simplicity of MYPro Create from the very first step: data input. Unlike with previous applications, Gerber or ODB++ files need to be imported just once for programming all Mycronic AOI, SPI and jet printing machines in the line or in the factory. “All the common data, including panel layout definition and PCB definition, is published from a central database to the different machines,” explains Milos. “This means that what you see in the software is what you publish for production, which amounts to a simple and straightforward user experience.” In addition to significantly reducing the time required for data preparation, the new data import workflow reduces the room for human error while still producing programs recognized by each of the individual machines.

Faster compilation, better quality

Data compilation is another significant factor when creating print and inspection programs for complex products. In short, faster compilation means faster availability of data for the machines in production. “Having one single software eliminates the hurdle of time-consuming multiple compilations,“ says Milos.

“For bigger jobs, it can also be scaled up to 10 instances, meaning that multiple projects can be compiled simultaneously. This further increases the data throughput of the whole software system. Whether you have multiple users and no longer have to wait for compilation, or you’re a high-mix producer with frequent changeovers or a mid-volume producer with large volumes of data to manage, the new software both saves time and ensures better print quality. And for the creation of jet printing programs, MYPro Create is significantly faster than its predecessor.

Better deposit control and design freedom

Compared to previous software, MYPro Create makes jet deposits easier to search and modify. Simply search for part numbers, adjust paste volumes for different package types and freely adjust deposit properties as needed. “Now there’s total freedom to adjust the volume or shape of a single deposit,” says Milos. “Operators have precise control over each deposit’s size, form and position directly through the user interface. It’s just a matter of changing the deposit onscreen with your mouse or keyboard, and you’ll see it change live in the compiled preview. The result is more granular control of deposit properties, leading to better quality solder joints, post-reflow.”

Improved visualization layers

For MYPro I series 3D AOI or PI series 3D SPI users, MYPro Create allows for importation of board scans from SPI or AOI directly into the job creation program. Jet printing programs can be seen as they are created, in their actual context, giving operators better visual control over the full production process. “If you have the board scan — bare board or PCBA — available, the process is even more intuitive,” says Milos. “Rather than basing your inputs on source file data, which can differ from real-world conditions, you just align your program with the underlying image. So instead of inputting individual dimensions, you’re aligning all the machines’ job programs around the actual location of every part on the board, which is much better from a quality perspective.”

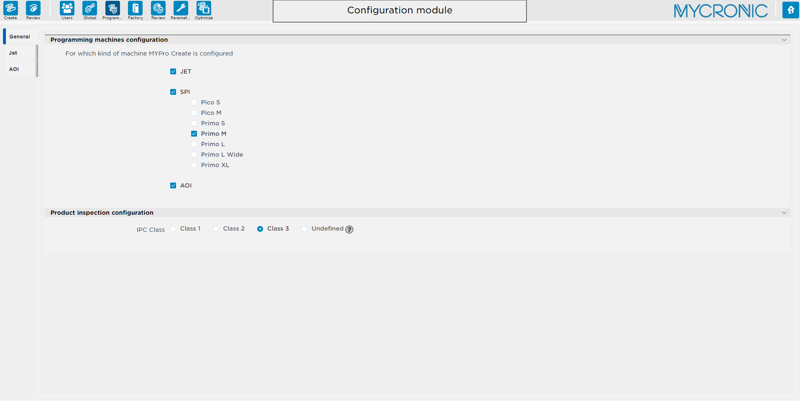

Configure new programs for any or all Mycronic jet printing, SPI and AOI equipment.

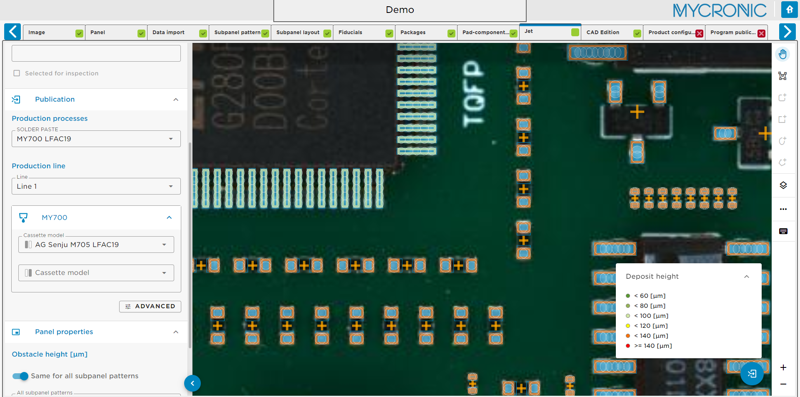

Advanced deposit editing including deposit size, shape and position with compilation preview.

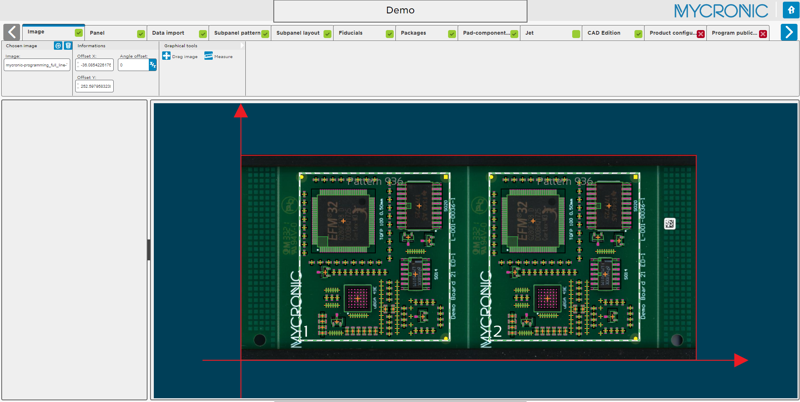

Import PCBA scan from AOI for visual alignment with SPI and Jet printer program data.

Operators have precise control over each deposit’s size, shape and position directly through the user interface.

Step-by-step guidance

In today’s software landscape, a clean and intuitive user interface is far more than a design feature: it’s essential to a productive, error-free user experience. With its logical and self-explanatory visual guidance, and a right-to-left tab structure that follows the assembly process, MYPro Create makes easy work of even the most complex job creation tasks. It visually indicates completed steps, incomplete actions and errors, helping even novice programmers learn as they go.

“SPI and AOI users will probably recognize the visual guidance language from MYWizard,” says Milos. “We’ve applied the same philosophy in MYPro Create, with clear, color-coded visual signals showing what actions need to be made, and in what order. We know our users are handling a lot of complexity in their day-to-day operations, so we try to keep it as simple – yet helpful – as possible to maintain their focus and avoid information overload.”

Working together

As Milos is quick to emphasize, the new MYPro Create is a significant step forward for jet printing and inspection customers — but it is just one part in a long-term effort to create a unified, full-line programming software experience. “This is just the beginning of a long journey,” he says. “And it wouldn’t be possible without continuous customer feedback. Because all the development is in our hands we can iterate more quickly, address issues, add features and release more frequent updates. Our users have already told us the experience is more stable, more reliable and easier to follow than any jet printing software they’ve used before.”

Based on initial customer feedback, Milos is confident that the journey is headed in the right direction. “Just the other day a jet printing customer told us he’s considering changing his inspection equipment to an I series AOI,” he says. “He’s been beta testing MYPro Create for his MY700 and sees a lot of value in our common programming interface, and in being an active partner in the development process. This tells me we’re on the right track as we pursue the ultimate goal of a single line programming software for all Mycronic machines, together with our customers.”