Decreasing the environmental impact of the SLX mask writer

- through product life cycle analysisWhen a product is manufactured, it goes through a life cycle that starts with raw material acquisition and ends with the disposal of the product. To understand how our products affect the environment, Mycronic has completed a life cycle analysis of a relatively new product - the SLX mask writer. Engineered to use little electricity, the analysis revealed that the main environmental impact caused during the lifecycle of the SLX was compressed air.

Everything that is produced goes through five main life cycle stages: material extraction, manufacturing, packaging and transportation, use and end of life. At each of these stages, there are inputs and outputs, flow-throughs, value losses, and potential gains. An environmental life cycle analysis (LCA) evaluates the environmental impact of a product through each stage of its lifetime. The purpose is to better understand the environmental impact and resource flows that exist.

The analysis is then used to identify what a manufacturer or organization can do to reduce the environmental impact of its products and services. Given the urgent need for reducing global warming, the life cycle analysis is a primary and crucial tool used to support decision-making for sustainable development.

Mycronic’s efforts to assess the impact of one of the most popular products thereby sets us apart from most industry peers.

Life cycle analysis for large industrial machines

Life cycle analysis are more commonly performed for conducting impact assessments of consumer products. The large industrial machines that are used to manufacture these consumer products are not often fully assessed for their environmental impacts. This means that although both the manufacturers and users of these large industrial machines can benefit from having information regarding the impact of the machines, this information is often unavailable. Mycronic’s efforts to assess the impact of one of the most popular products thereby sets us apart from most industry peers.

Snapshot of the SLX life cycle analysis findings

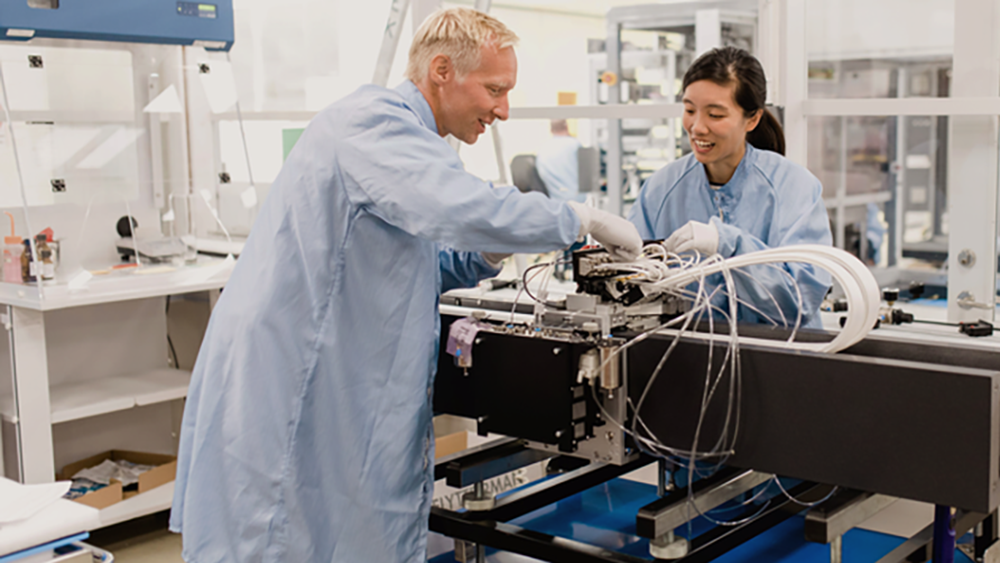

In late 2019, Mycronic launched the SLX, a new and modern mask writer for the semiconductor industry. The new mask writer addresses a growing market that also has a significant need for replacement and modernization. The SLX was engineered to use very little electricity in its entire life cycle, enabling substantial energy savings during the use by the customer. To identify ways to further reduce the impact from this and other mask writer products, and to enable comparisons, an environmental life cycle analysis was conducted.

The SLX life cycle analysis report found that the largest environmental impact, which is defined as a combined effect on the components of the environment, during the life cycle occurs when the customer uses the machine. In fact, the user phase represents an entire 90% percent compared to a mere 6% of impact produced during manufacturing.

The largest impact from a mask writer usually stems from its energy-intensive laser. For the SLX, the laser only accounts for 2% of the impact. Instead, compressed air expended when using the machine accounts for the main impact. Because compressed air uses so much energy, it is important that facilities look for ways to reduce their environmental impact to offset energy consumption.

These findings give us insight on the next steps to take to innovative more efficient solutions for tomorrows electronics.

#SLX #SUSTAINABLEDEVELOPMENT #LCA