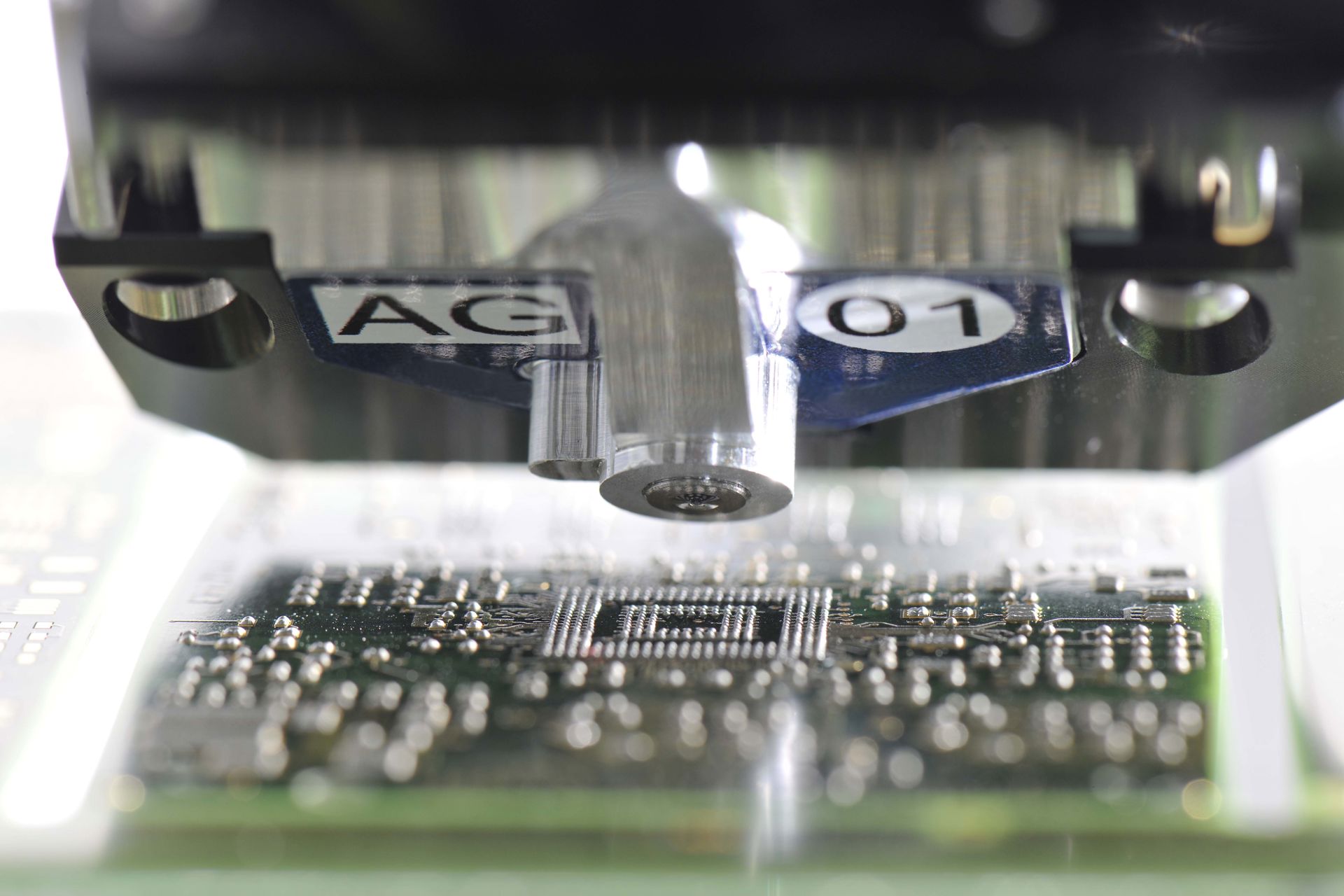

Perfect solder joint with jet printing

The reliability and efficiency of your solder paste deposition process has a direct effect on the performance and profitability of your SMT production line(s). In addition, its capability to handle complex PCBs, with growing component diversity in types and sizes, can positively influence your competitiveness.

Jet printing technology revolutionizes SMT assembly by combining a near-zero defect solder paste deposit process, with the highest flexibility. While eliminating the recurring costs of stencils, it provides unprecedented accuracy and reliability in the production of solder joints for all types of SMT components.

Why should you attend?

In this webinar you will have the opportunity to:

- Understand the basic principles of jet printing

- Discover the technical capabilities of solder paste jet printing

- Consider its operational benefits