MYPro I50X - 3D AOI

- AI AI-powered interface for fast and reliable programming

- Accurate High accuracy and production stability

- All-in-one All-in-one inspection capabilities

High-performance 3D AOI for high-mix production

The MYPro I50X brings high-performance 3D AOI within the reach of high-mix electronics producers, thanks to the extreme versatility of its inspection capabilities together with MYWizard, our next-level AI-based programming interface that reduces programming time by up to 30%.

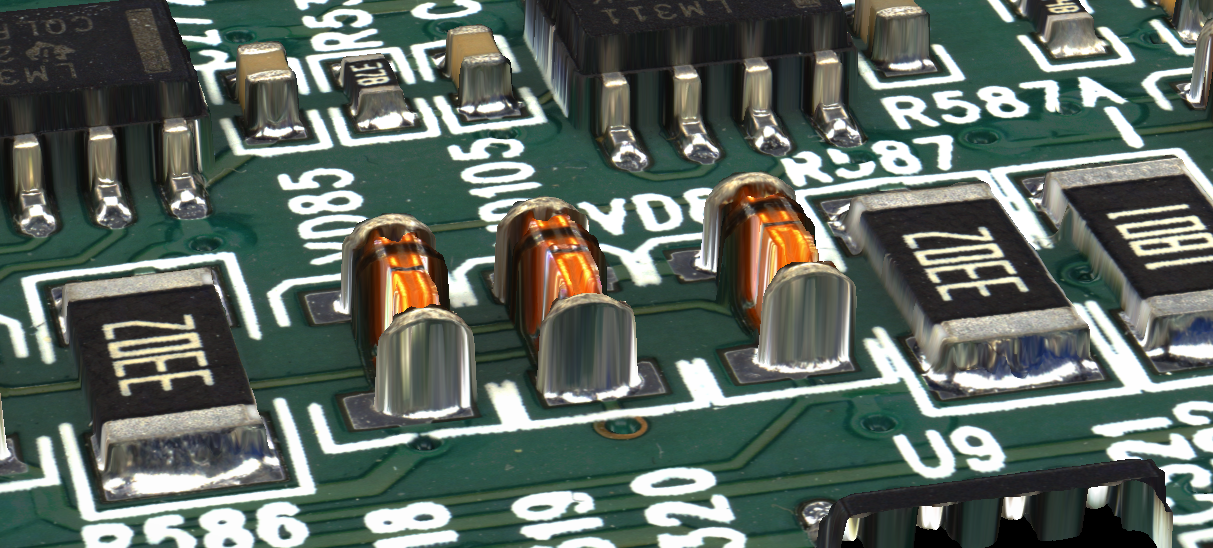

MYPro I50X’s comprehensive test coverage enables 3D inspection of all SMT, THT and press-fit components, both at the pre-reflow and post-reflow stages.

MYWizard, a game changer in 3D AOI programming

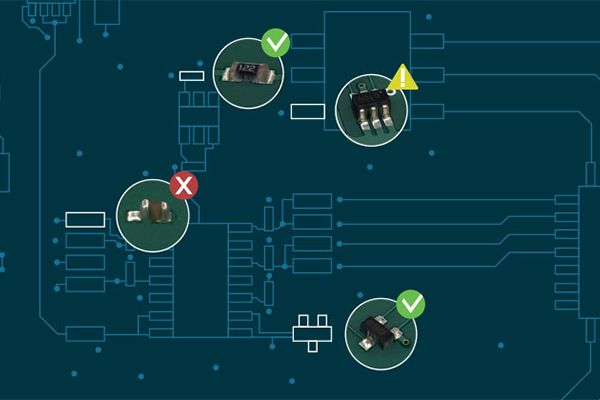

To guide operators through programming, the new MYWizard user interface integrates two artificial intelligence systems – Auto-Matchmaker, an advanced component recognition technology, and new machine learning algorithms that inspect fiducials and component’s polarity. It results in up to 30% reduction in programming time compared with previous generations, with reduced programmer experience and training.

Escape Tracker for automated performance optimization

Next-generation self-checking system for inspection performances

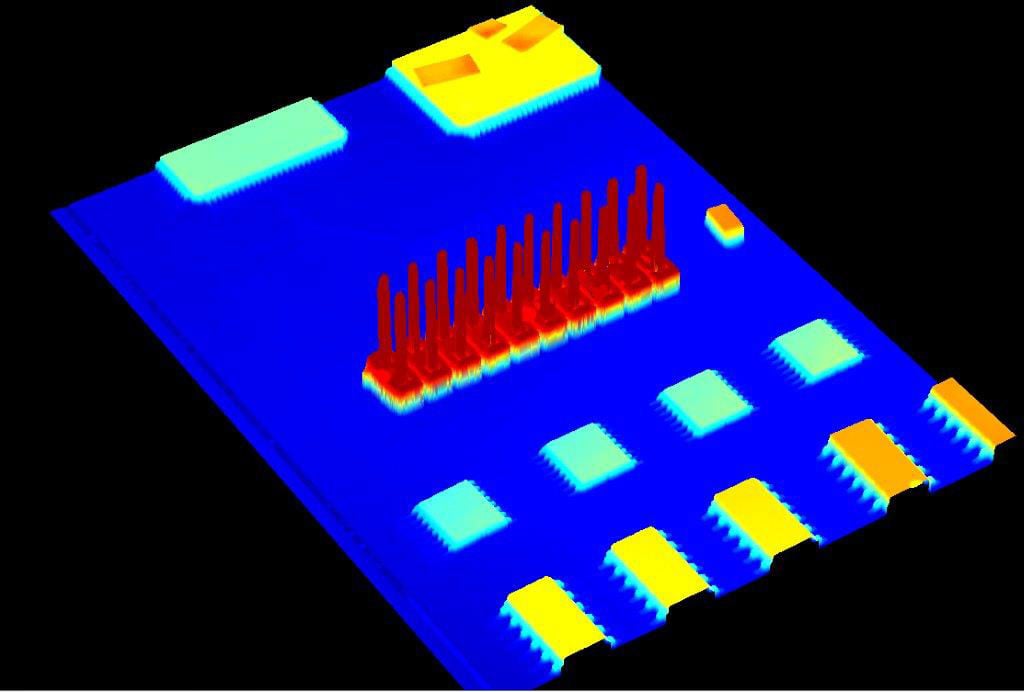

Iris™ 3D vision technology

High-performance inspection. Accelerated.

Sharper 3D imaging

Industry-leading performance and production stability

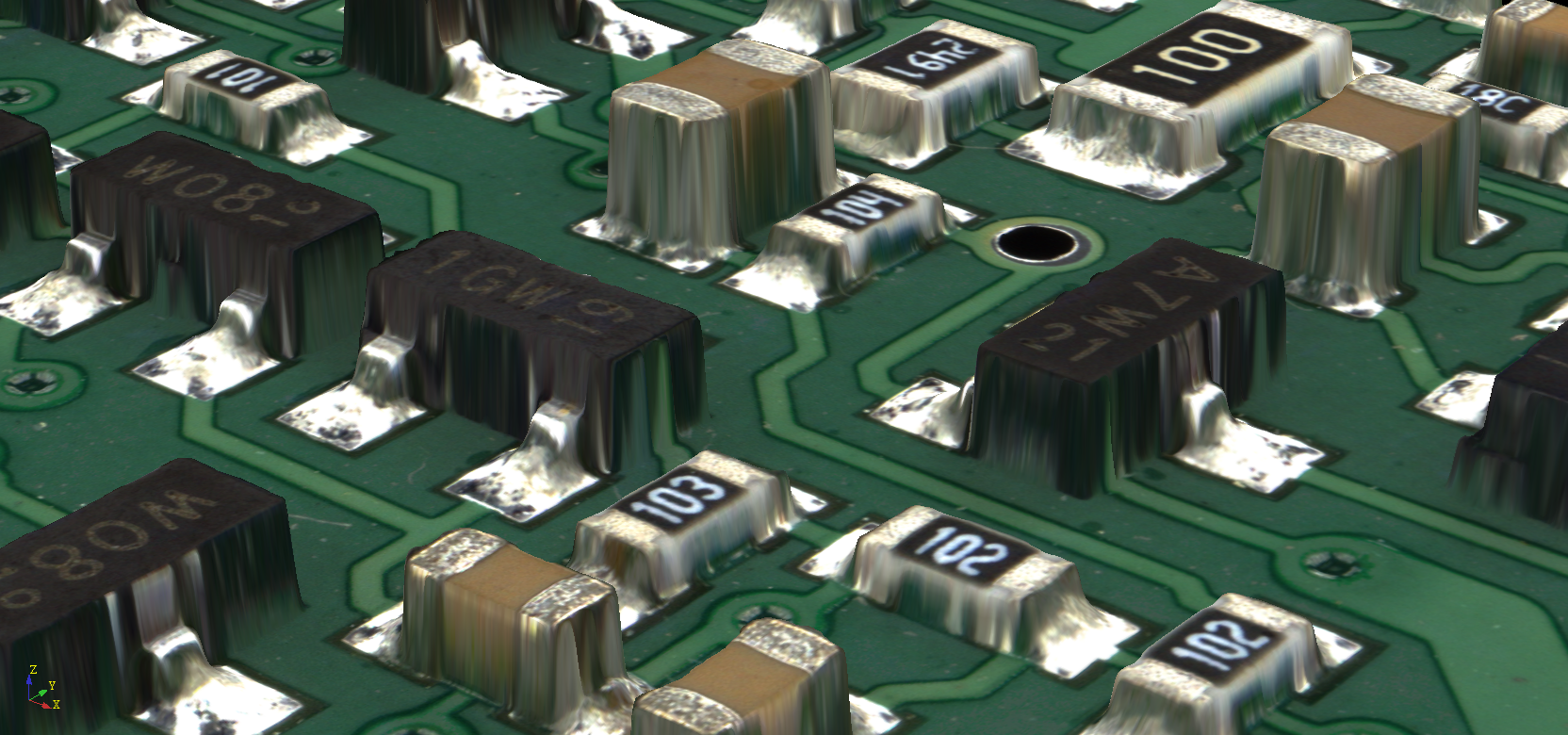

The MYPro I series offers best-in-class accuracy and repeatability in X, Y, Z and Theta for efficient process control. The unique combination of sub-pixel geometric pattern matching technology, proprietary 3D algorithms and unique warpage and distortion compensation leads to superior critical measurement capabilities.

- Vectoral imaging pattern matching.

- +/- 5 mm warpage compensation with full Z accuracy.

- 3.5 μm X,Y resolution with sub-pixel technology

- Constant 1 µm Z resolution, from -5 up to 20 mm in altitude

All-in-one inspection capabilities

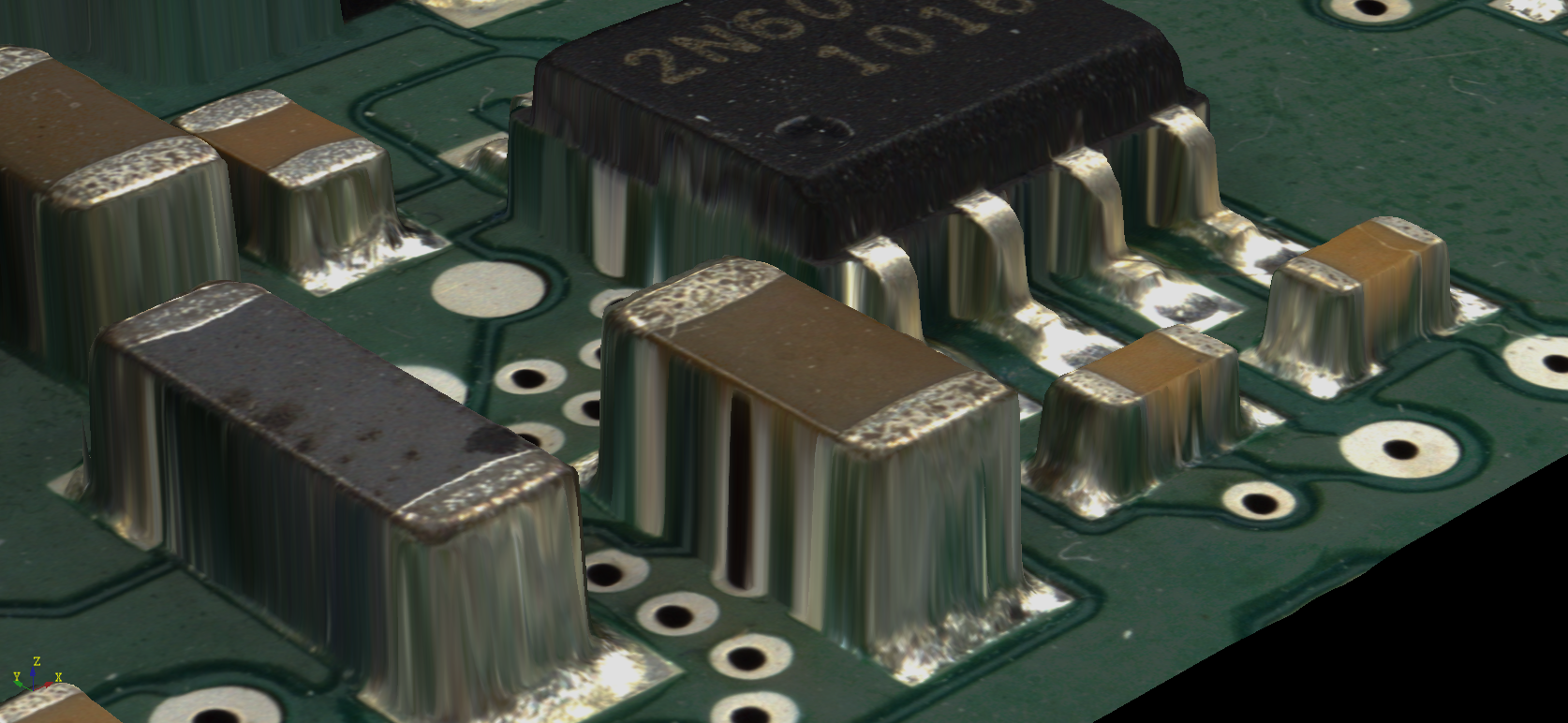

With full test coverage, the MYPro I series measures the component body, leads, and solder joints with the utmost accuracy to catch any type of defects.

Its comprehensive toolbox of ready-to-use 2D and 3D inspection tests allows the MYPro I series to inspect not only all SMT components, but also through-hole components, press-fit components, connectors of all types and shapes, and any new packages.

Fully integrated process control

MYPro Link

MYPro Analyze

Contact