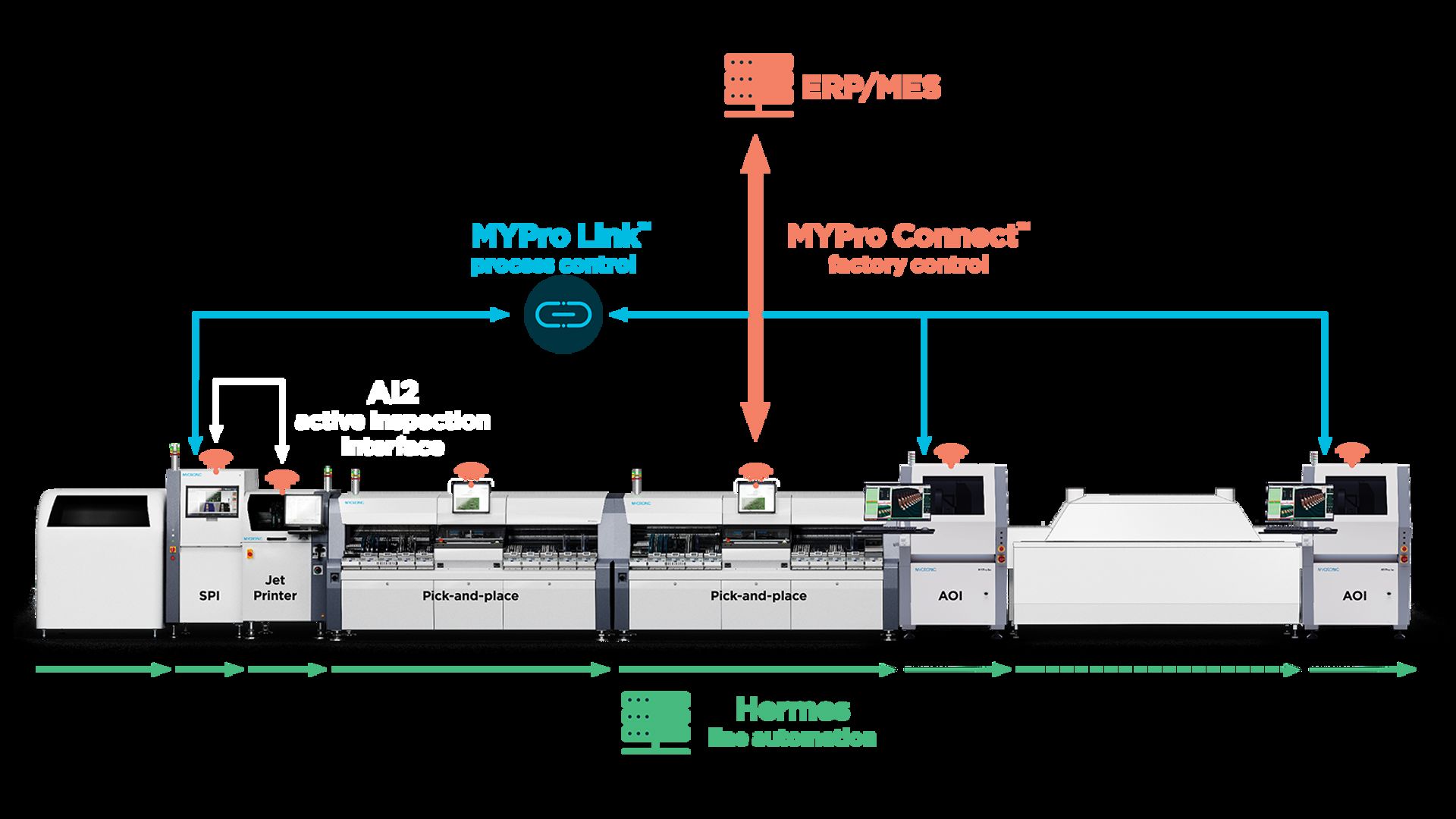

MYPro Connect

- Monitoring and traceability Enables export of data from SMT assembly line(s) to calculate production KPIs (OEE, FPY, etc.), WIP tracking, and factory-wide traceability.

- Changeovers Remotely manages recipes, handles changeovers and prevents errors in program selection, especially when switching between variants.

- Interlocking Interlocking allows the state of each board to be validated before continued processing, automatically verifying incoming PCB ID with the program loaded on the next equipment.

Full factory connectivity – zero custom integration.

Factory connectivity has never been simpler. With MYPro Connect, you can connect any MYPro series SMT equipment to any enterprise system while keeping costs fully in your control. No in-house customization. No lengthy implementation. And no future disruptions. Just a single standard IPC-CFX interface that’s ready to plug and play, whatever your Industry 4.0 strategy may be.

IPC CFX — Tomorrow's standard for factory connectivity

With MYPro Connect, Mycronic eliminates the need for specialized software interfaces by bringing IPC CFX standards to all assembly equipment.

Reduce costs and complexity

The MYPro Connect platform enables plug-and-play connectivity with all IPC-CFX-compatible MES and ERP systems. For other non IPC-CFX-compliant MES, the same features can be implemented through customized integration from Mycronic, making implementation of all leading MES protocols more flexible, predictable and cost-effective than ever before.

Stable, reliable connectivity

MYPro Connect is designed to bring the productivity and flexibility Mycronic equipment is known for into the industry’s most advanced enterprise systems. Whether your ambition is to implement or improve centralized monitoring, MYPro Connect’s standard data exchange ensures stable connectivity for a wide range of machine-to-business and business-to-machine functions.

Software for the electronics factory

MYPro Connect follows IPC-CFX standards and offers

easy factory integration of any MYPro series SMT

equipment to any enterprise system while keeping

integration costs fully in control.

The MYPro Link process control software suite is a

real-time web-based interface for unifi ed SPI and AOI

data, its rapid data correlation and analysis delivers

powerful possibilities for measuring, controlling and

anticipating process variations.

The Hermes standard (IPC-HERMES-9852) is a modern, open, non-proprietary and vendor-independent protocol for machine-to-machine communication in SMT assembly lines. It provides flexible data structures to seamlessly exchange all essential types of board related and is a key enabler of a controlled and transparent board flow management.

The exchange of information (AI2) between the PI series 3D SPI and the MY700 Jet Printer enables fully automated control of print quality. The SPI simply informs the jet printer about which board needs to be repaired using the PCB’s unique ID code, and sends the information about the location and volume of paste to be added.

Brochure

Contact