MYPro Link

- MYPro Create Easy programming of your Mycronic SPI and AOI

- MYPro Review Results at a glance

- MYPro Live Real-time yield management

- MYPro Analyze Powerful yield improvement

- MYPro Correlate Optimized process control

One step closer to perfect.

The MYPro Link process control software suite helps to achieve new levels of product quality and process automation. A real-time web-based interface for unified SPI and AOI data, its rapid data correlation and analysis delivers powerful possibilities for measuring, controlling and anticipating process variations.

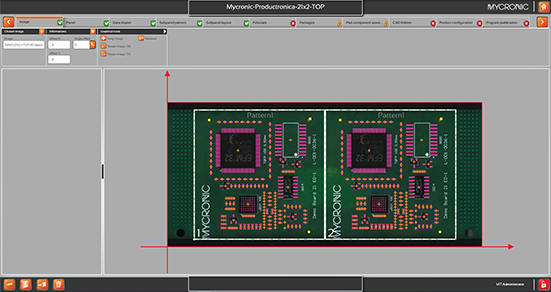

Easy programming with MYPro Create

MYPro Create is your central console for programming your Mycronic SPI and AOI inspection equipment simultaneously. MYPro Create generates inspection files from standard Gerber and CAD data which simplifies data preparation. Assisted by artificial intelligence, inspection equipment programming time is drastically reduced, by up to 30% on AOI, while ensuring database uniformity between all SPI and AOI in operation.

- Integrated one-stop data import software for both SPI/AOI for data correlation and traceability.

- Variants management to ease program management in high-mix environments.

- Intuitive, easy to use and to maintain.

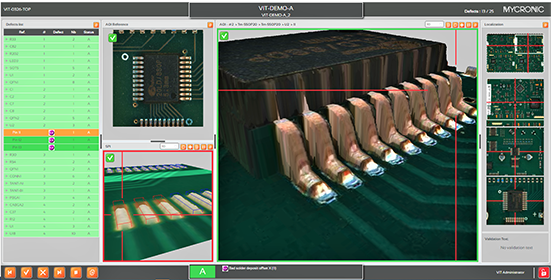

Results at a glance with MYPro Review

MYPro Review gives operators an easy way to make pass/fail diagnoses at a glance. By automatically correlating SPI and AOI results into a single on-screen overview, it not only provides a highly accurate and simplifed defect classification system, but also helps fine-tuning SPI tolerances for optimal first-pass yield.

- Review high-quality 3D defect images to localize defects at a glance.

- Easy classification using reference images.

- Use IPC or user-defined defect categories.

- Speed up reaction times with pre-defined corrective action messages.

- Optimize review environment with customized screen layouts.

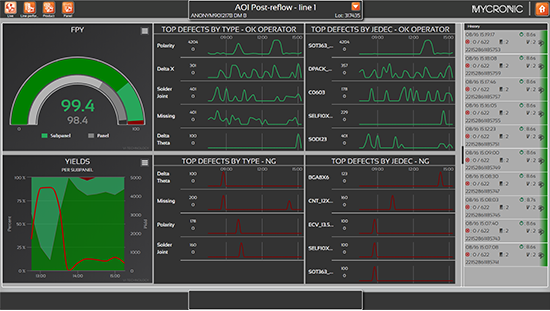

Real-time yield management with MYPro Live

The MYPro Live module instantly highlights production deviations and trends, allowing you to take immediate action to improve your yield. Thanks to intuitive web-based and mobile interfaces, it enhances agile yield management with a range of real-time insights.

- Monitor key process indicators at SPI or AOI from anywhere, including on mobile devices.

- Track the root cause of process deviations.

- Remotely monitor your entire shop floor.

- Display actionable information to your operators.

- Eliminate waste.

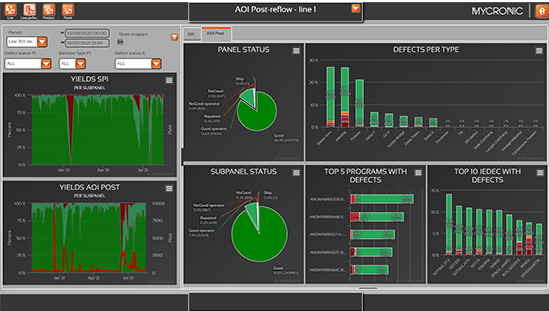

Powerful yield improvement with MYPro Analyze

MYPro Analyze enables continuous yield improvement using powerful data mining algorithms and root cause investigation. The beauty of MYPro Analyze resides in its intuitive and extremely precise drill-down feature which allows to identify in a few clicks the root causes of a defect.

- View FPY, FTY and DPMO calculations

- Monitor process capabilities including uptime and downtime trends

- Generate daily, weekly or monthly quality reports to support 8D problem-solving and lean initiatives

Optimized process control with MYPro Correlate

The MYPro Correlate module ensures that process control tolerances are optimized at all steps by correlating SPI and AOI defect information. This makes it possible to substantially improve line efficiency while expanding defect coverage and minimizing operator review.

- Adjust SPI and AOI program tolerances based on accurate data and images

- Eliminate false sanctions by operators

- Build process knowledge by tracing defect evolution along the line

Brochure

Contact