PI Pico - 3D SPI

- Highly accurate 3D inspection Patented Z-referencing technology for paste volume measurement.

- Superior repeatability Multi-frequency, multi-pattern moiré and patented dual Z-axis motion.

- Auto-programming SPI Machine learning algorithms, facilitates for operators of all experience levels.

High accuracy and repeatability 3D SPI with auto-programming

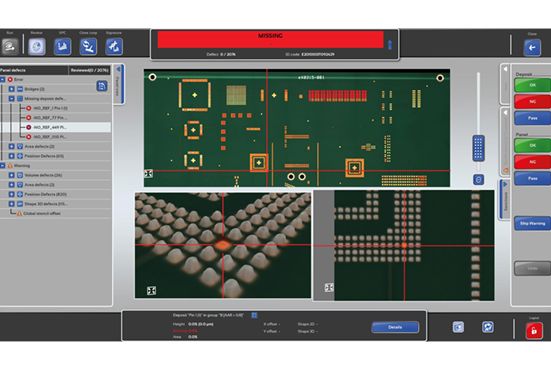

Clear and simple inspection control

Clarity and simplicity are words rarely associated with the complex process of solder paste inspection (SPI). But the PI series changes this. Thanks to an intuitive touchscreen interface, it can easily be set up and run by anyone with just an hour of training. Calibration requires only the touch of a button. The machine programs itself after a single bare board scan. And performance remains consistent across SMT lines — with no fine tuning.

Measure paste volume with unmatched accuracy and repeatability

Z-referencing is the key to accurate solder paste inspection. This is why, rather than referencing just a small cropped area around the pads, the PI series captures hundreds of references across the ultra-large 3D field of view. As a result, you always know the exact volume of paste deposited on even the smallest pads. Regardless of board warpage, your measurements remain accurate in all types of real production environments, with no false calls.

Take control over the print process

To further enhance your process control, the PI series utilizes automatic pad grouping by area aperture ratio (AAR). This allows you to continuously improve your process and set tolerances independent of products. It also provides extra-large 3D review images for easy diagnostics. Whether you’re using the built-in closed-loop function to improve yields or monitoring your process in real-time with MYPro Live, the PI series gives you total control over the print process to ensure better products and higher yields with every batch. To keep track of your performance over time, MYPro Analyze helps you report and monitor your progress, generating useful insights and trend analyses.

Stable and accurate Z-reference

MYPro Analyze

Synergy with MY700 Jet Printer

Brochures

Contact