MYPro S20 - stencil printer

- High accuracy Smart vision system for precise printing setup and monitoring, for any PCB designs.

- High repeatability Solid mechatronics design coupled with 2D inspection and statistical process control.

- Flexible and user-friendly Fast setup time and automated cleaning operations.

High accuracy meets high flexibility

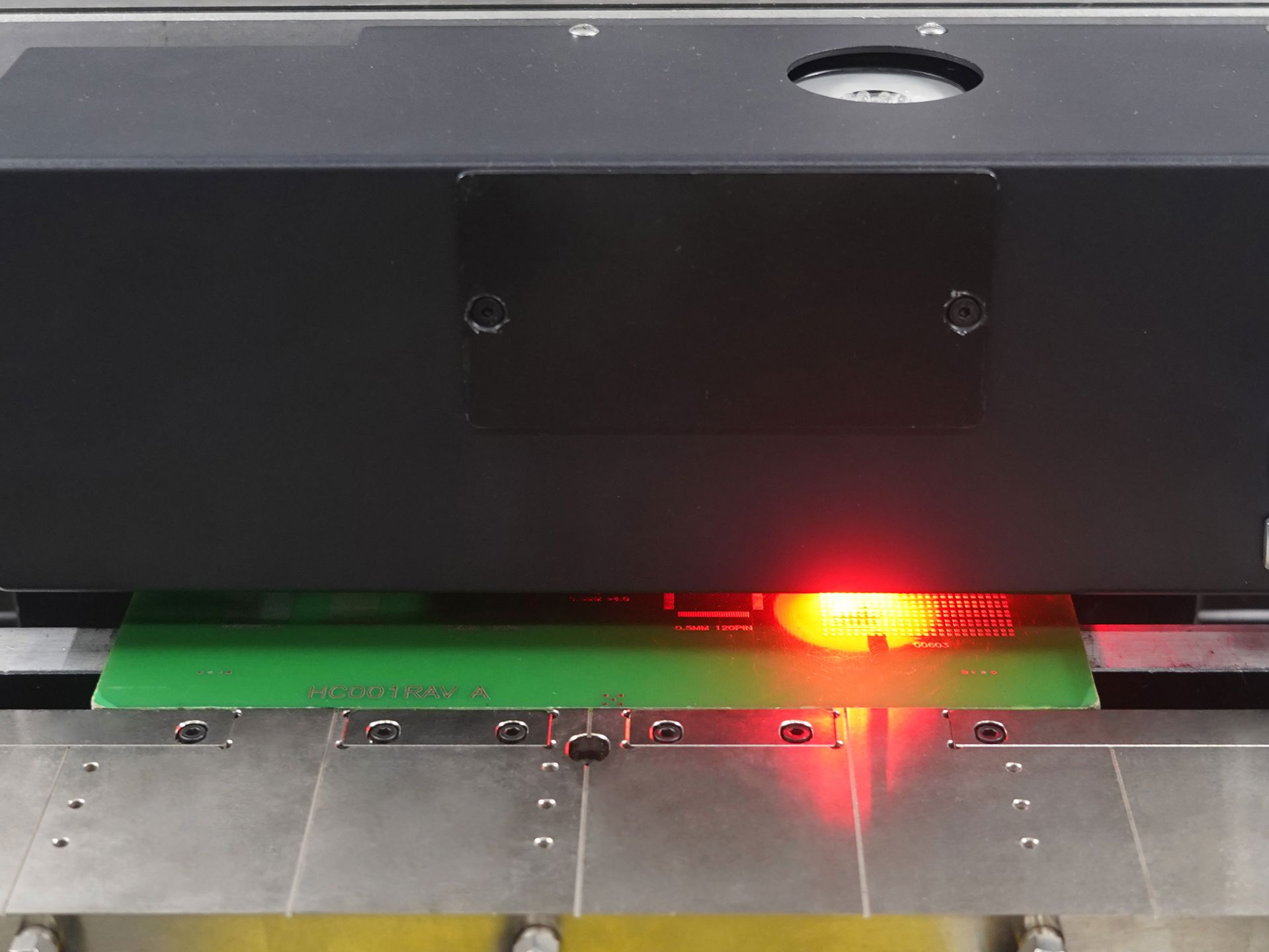

In the MYPro S series, an advanced vision system ensures complete alignment between the stencil and PCB, while a climate control feature maintains the physical qualities of the solder paste to ensure consistent print quality.

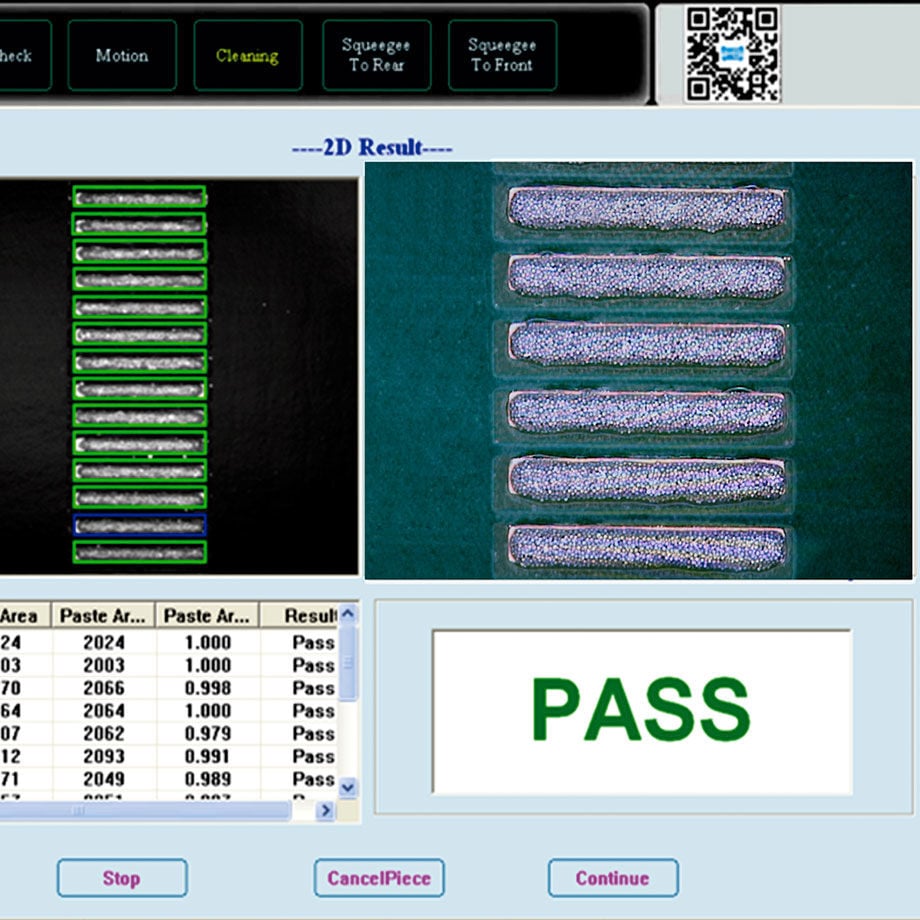

During the printing phase, squeegee pressure is permanently monitored, and any deviation is displayed on the control screen for immediate correction. Each printed board can be 2D inspected to ensure that no deposits are missing, and after each stencil cleaning phase, the stencil itself is 2D inspected to make sure it is valid for production.

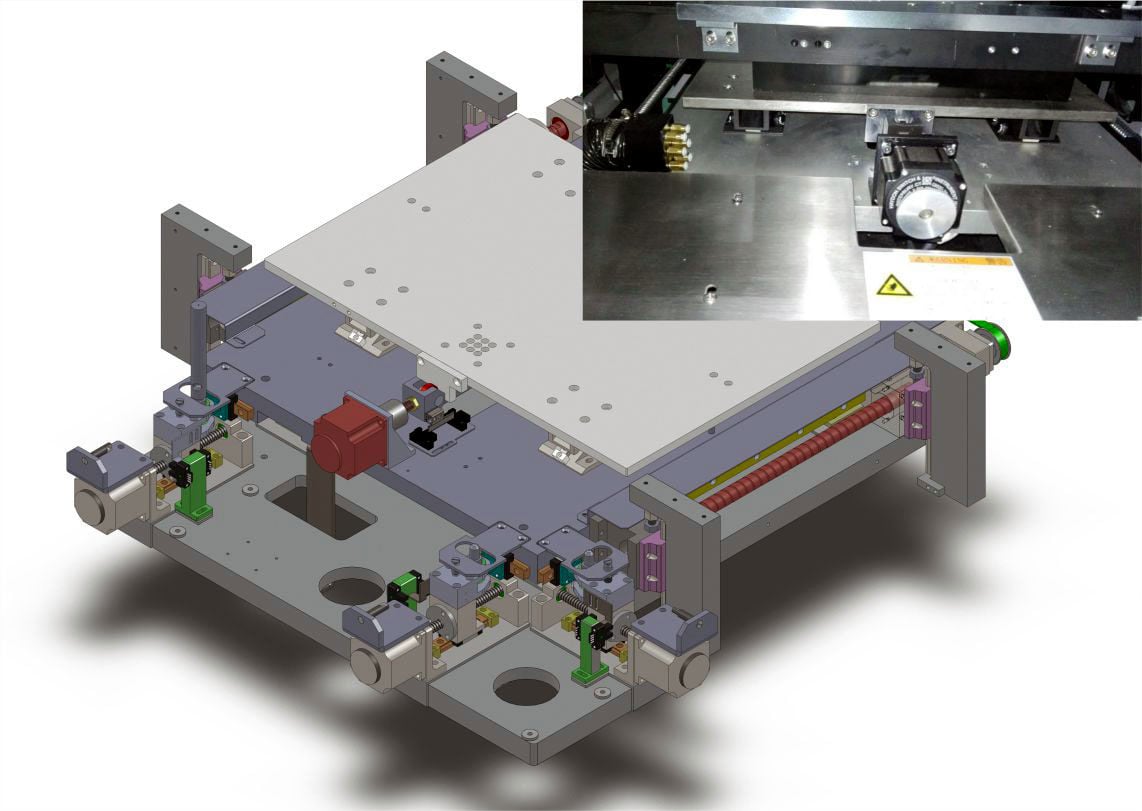

Solid foundations

The printer has a robust frame with a marble support beam achieving high rigidity and repeatability of ± 8μm. Squeegee movement uses a ball-screw with direct servo connection which adds to long-term consistent printing. The transport rail is motorized with dual guide rails and dual ball-screw, ensuring long-term stability.

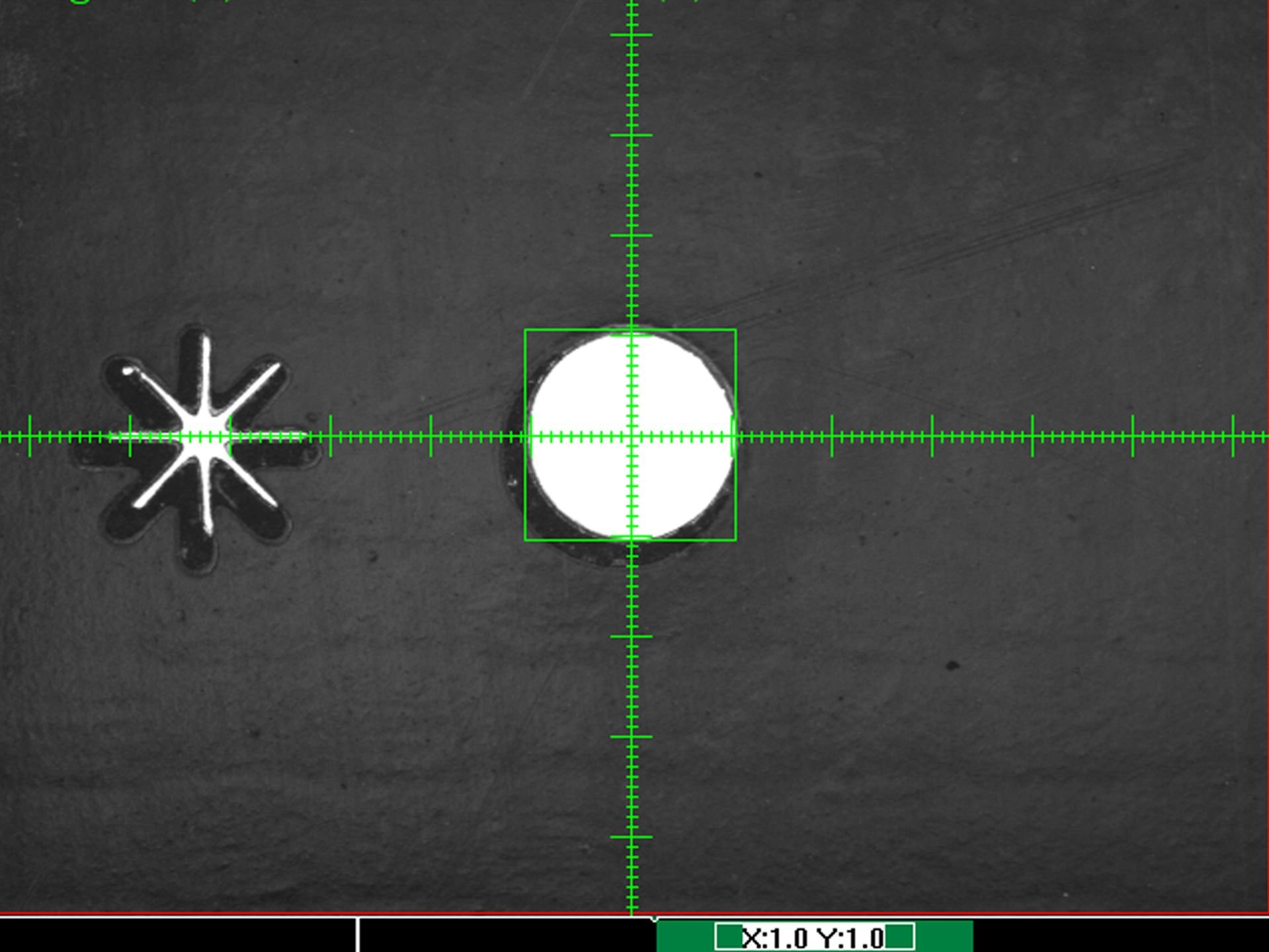

Intelligent vision and 2D inspection

Aided by intelligent adaptive lighting, the MYPro S series vision camera provides swift coverage with simultaneous upward and downward inspections.

Accommodate specialized fiducial marks on any pad from 0.5 mm to 3 mm in size. Print an endless variety of PCBs. And adapt settings with multiple light source options to handle a complete range of challenging designs.

Integrated 2D inspection and statistical process control (SPC) tools give you all the real-time data and analysis you need to ensure optimal print quality for every pad.

Closed-loop squeegee pressure control

Featuring pressure feedback display, automatic feedback compensation and pressure equalization, this system enhances printing process stability while extending the life of the stencil and scraper.

Motorized table height adjustment and Z-axis control

Motorized adaptation to various PCB thicknesses ensures perfect table flatness and fit for precise printing.

The lifting table improves movement rigidity through direct connection with the servo and ball screw. This enables precise control of the lifting position as well as controlled snap-off for improved printing yield.