Always one photon ahead – with industry ready 3D nano-printing and a full solution portfolio for Photonic Integration

Based on its globally unique IP portfolio for Photonic Wire Bonding and facet-attached micro-optics, Vanguard Automation - part of Mycronic Group develops process technology and machines for creating low-loss photonic connectivity between passive and active optical components. Our Photonics Interconnects solutions scale seamlessly from prototyping into volume production. We provide industry proven solutions for the telecommunication, datacom, machine learning, quantum industries and more. Our customers include companies and organizations seeking to advance their capabilities in photonic integration and packaging – overcoming todays challenges with tomorrows solutions!

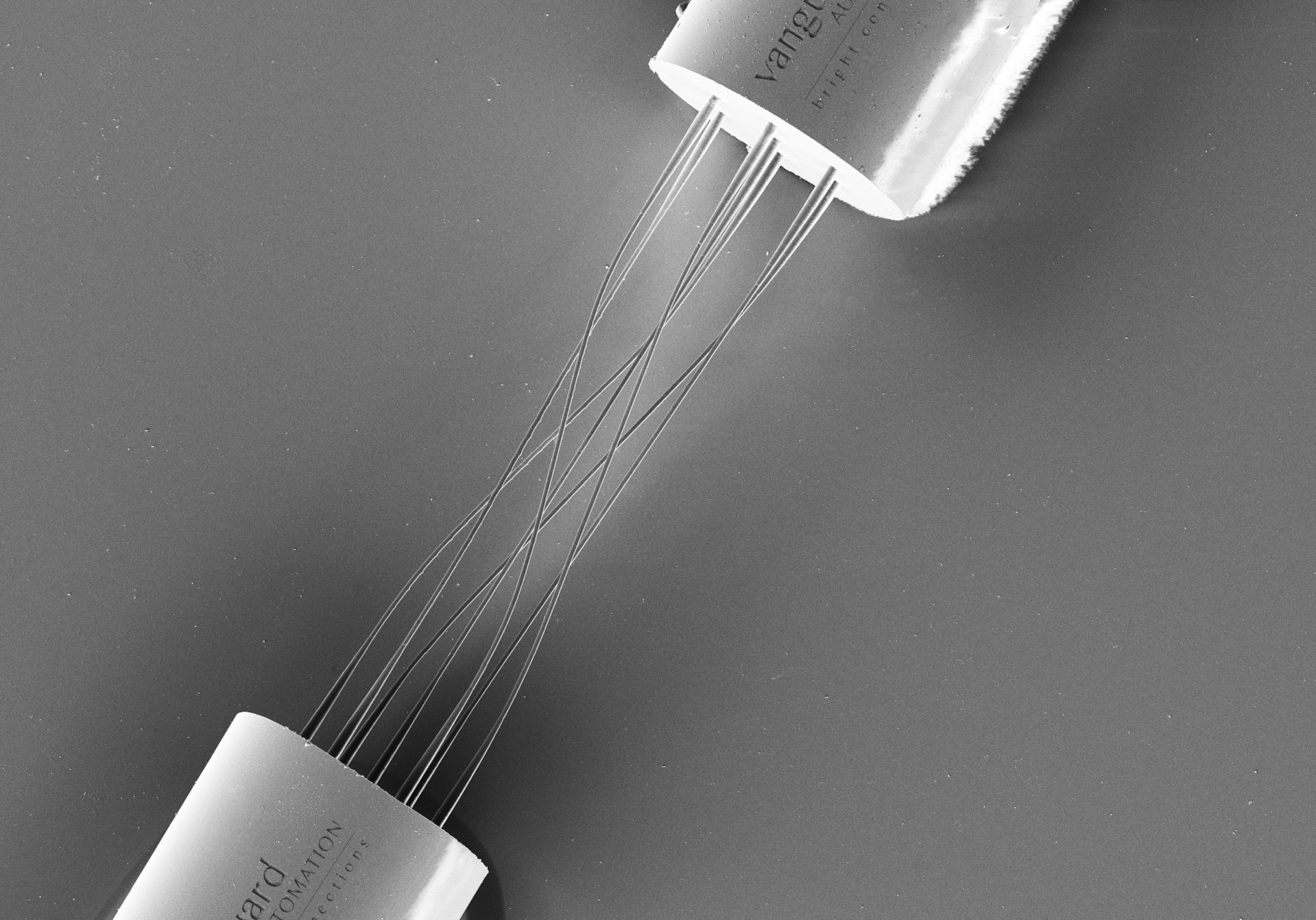

Our technology enables dense photonic integration, increased design flexibility and high fabrication throughput by leveraging advanced 3D nano-printing.

Headquartered in Karlsruhe, Germany, we develop the technology and products including machines, software, materials and processes for photonic packaging and integration. Our technology and products are rooted in over a decade of industry targeted research and development in integrated photonics at Karlsruhe Institute of Technology (KIT), and 20 years of experience in building high-precision assembly machinery for photonic packaging.

In the data center, telecommunication, artificial intelligence, and advanced sensing markets, our users are working with various material platforms, such as silicon, silicon nitride, indium phosphite, and lithium niobate to design and manufacture advanced photonic devices. The growing demand for scalable, reliable and flexible photonic integration solutions is driving our mission to provide customers with advance photonic packaging and assembly solutions with scalable industry proven 3D nano-printing technology for manufacturing.

Our machines and materials

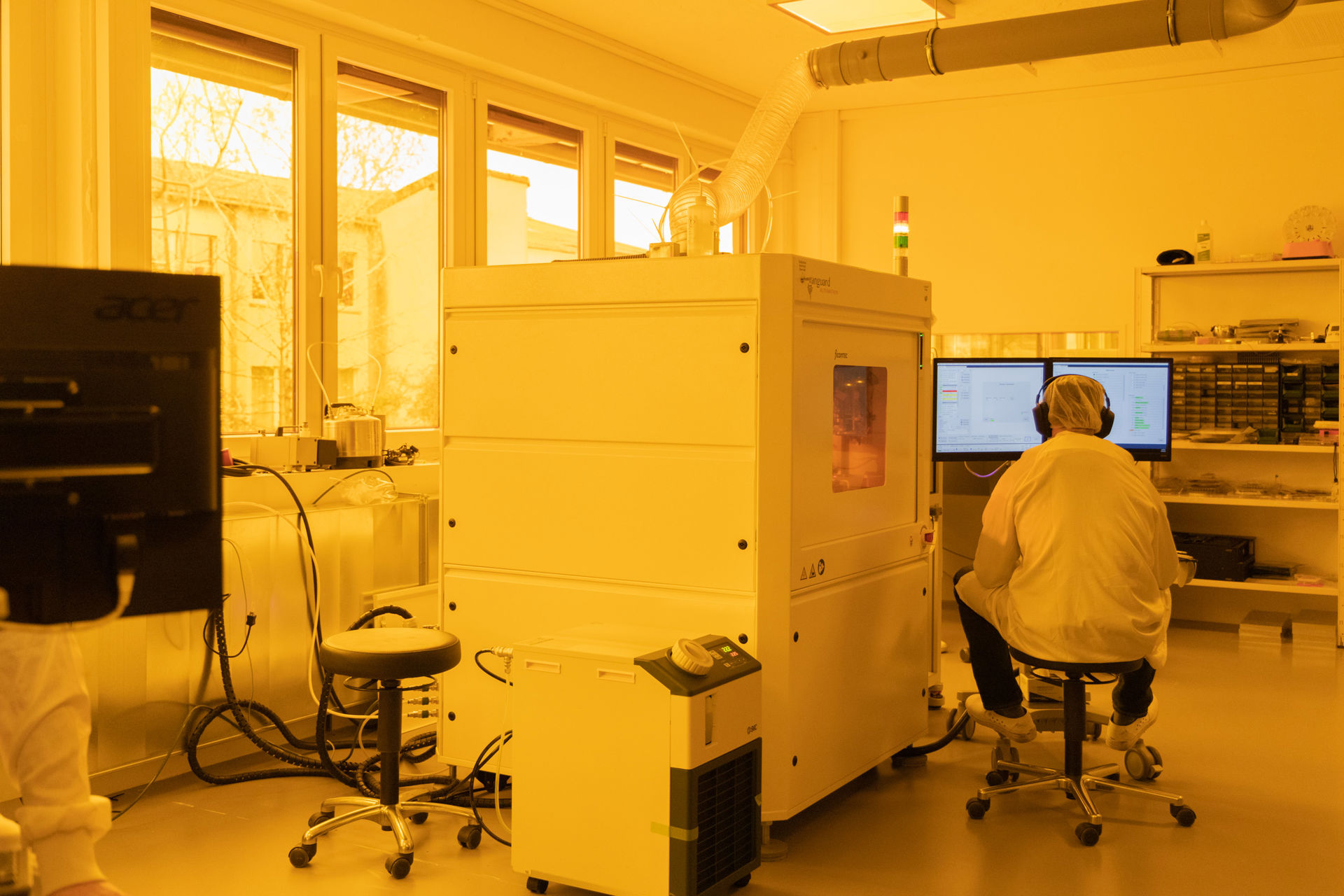

Our Machines - Industry ready 3D nano-printing

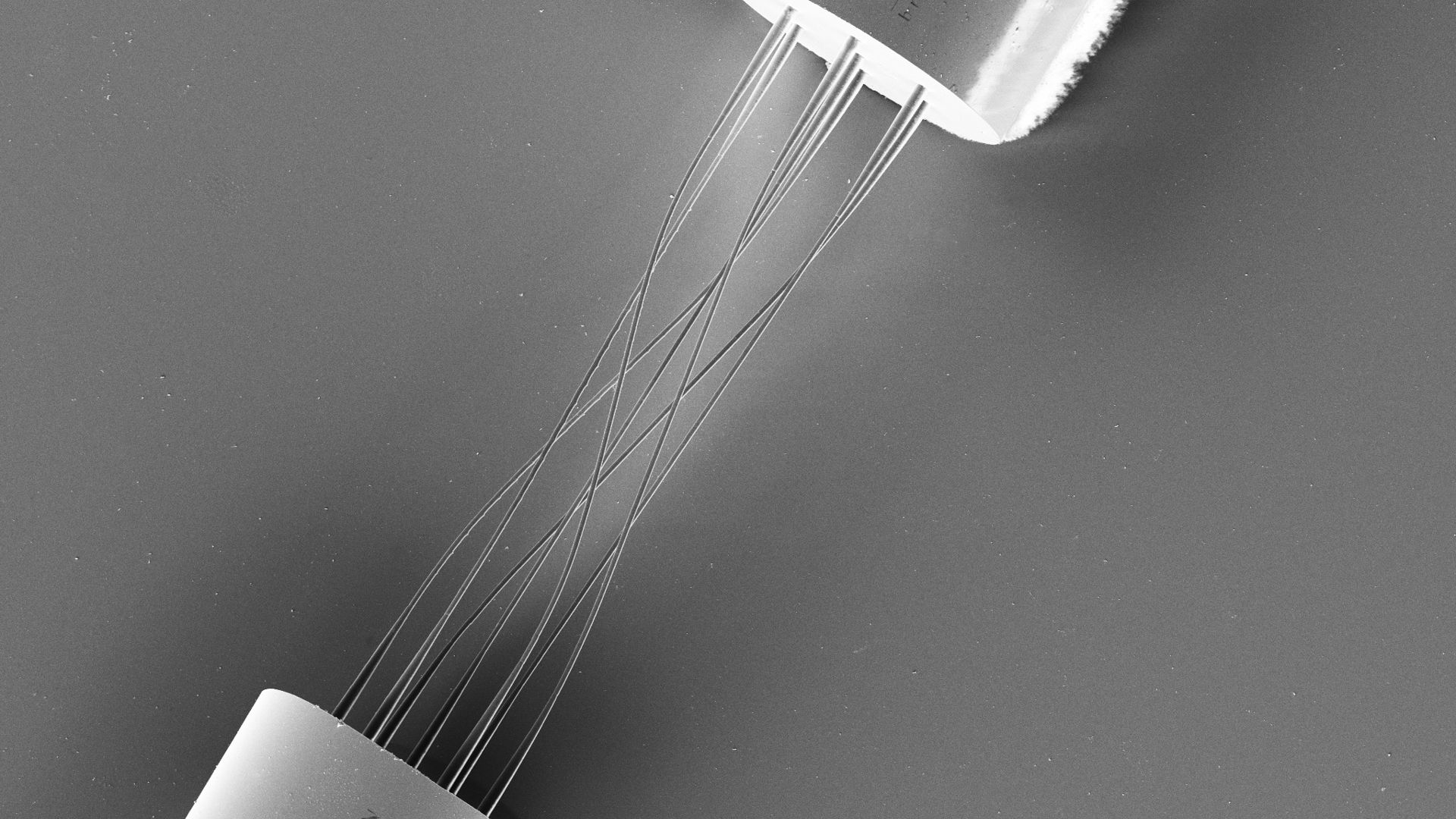

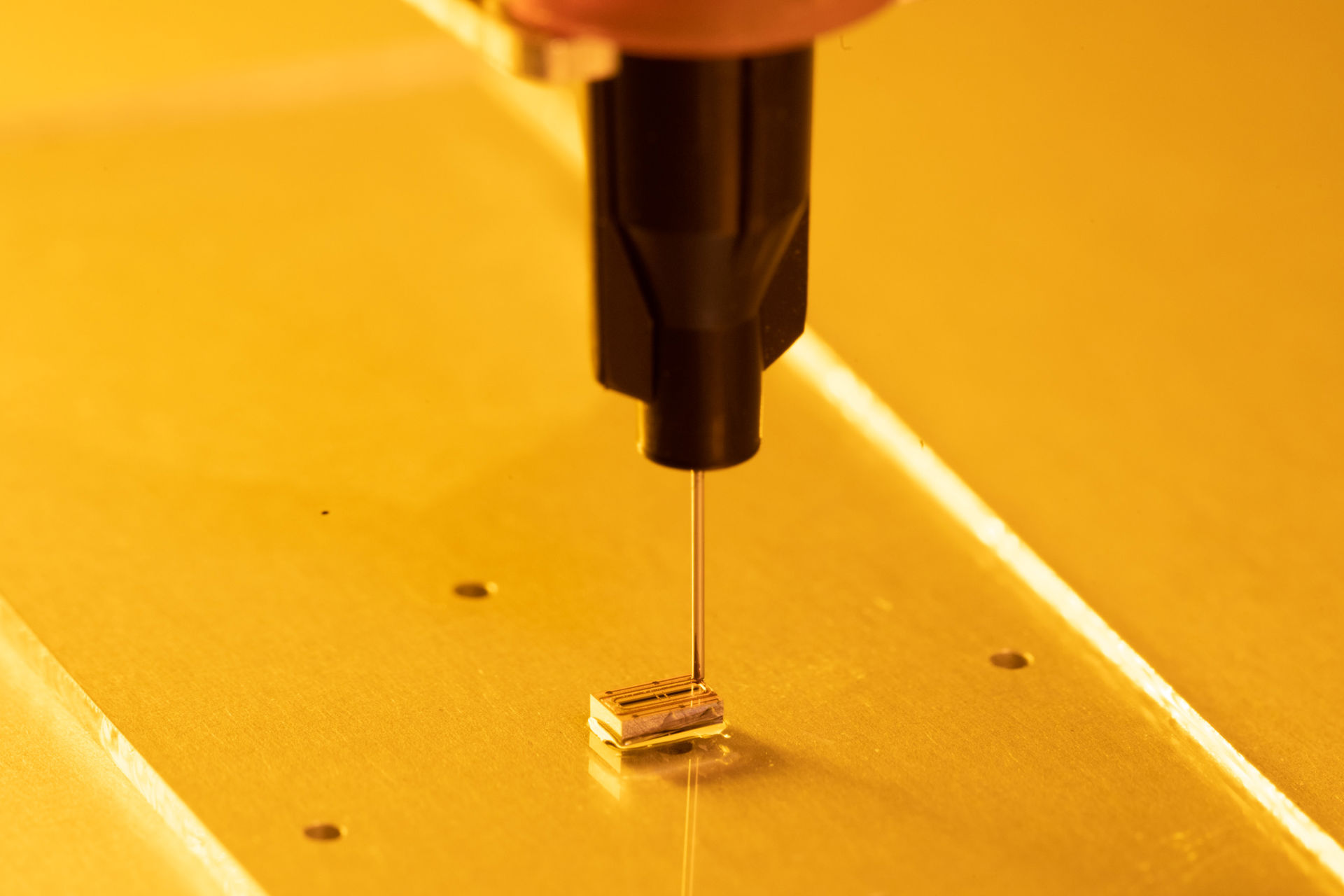

A powerful solution for photonic packaging and system assembly. 3D printing of freeform waveguides and micro-optical elements is revolutionizing photonic packaging and system assembly. With its SYMPHONY 1000 Series, we offer the first industrial solution for in-situ printing of Photonic Wire Bonds (PWB) and facet-attached micro-optical elements.

Our Materials - Complete Industry Grade Solution for photonic packaging

All materials are developed and formulated in house with full traceability. Our dedicated photoresists series VanCore, tailored to meet strict industrial reliability requirements, is proven to be reliable under the harshest environmental conditions.

Software and Technology

Our Software Control - Operated by powerful application software

BRIGHTWIRE 3D offers intuitive graphical machine and process control software for automated photonic packaging that includes all machine vision, positioning and system management routines required to reliably and repeatably drive the lithography process - fully flexible, fully automatic, fully remote.

Our Technology - Full Solution Portfolio for Photonic Integration

Explore the benefits of 2 Photon Polymerisation for hybrid photonic integration.