The power of partnership

How a decade of dedicated service supports the growth of PCB PowerIndia’s electronics manufacturing industry is booming, and PCB Power is one of the companies leading the way. Supported by one of Mycronic’s distributors Accurex, PCB Power, a Gujarat-based company, has been able to expand beyond PCB manufacturing to become a flexible full-service PCB assembly partner to a wide range of growing industries. India is quickly becoming a major player in the global electronics industry, with the government targeting for the country to become one of the top three global electronics exporters by 2026. As the industry has grown, PCB Power has emerged as one of the country’s leading PCB manufacturers.

A strategic expansion

Originally known as Circuit Systems, PCB Power was founded in 1995 with a focus solely on PCB manufacturing. Over the past decade, the strategy has expanded to include PCB assembly, where the company has built a niche serving some of the most demanding customers in the aerospace, railway, automotive, and medical industries.

The company’s business model is centered around taking orders online, offering a high-quality manufacturing service with fast deliveries. Flexibility is key for PCB Power, as they need to process extremely diversified jobs with the same efficiency and quality level.

“We decided to specialize in high-mix, low-volume,” explains Khushal Panchal, COO. “At the time, most EMS were focused on larger volumes. Ours were a series of less than one hundred, and very few were doing this type of work on automatic machines. We decided to turn this challenge into an opportunity.”

We decided to turn this challenge into an opportunity.

The hunt for flexibility

PCB Power understood their customers required small-to mid-volume batches, short delivery times, and flexible assembly, Khushal set out to evaluate his equipment options. “On top of the flexibility, we were looking for high precision . Because PCB Power is known for quality first and service second, we knew that any quality issues, for example with smaller components, would damage our brand.”

At Productronica India 2016 , he was introduced to the MY200 pick-and-place solution by the team from Accurex, supplier and service provider for Mycronic pick-and-place and jet printing equipment in India. “We saw the demo machine there and could almost immediately decide this was the right way to go,” says Khushal of the MY200. “We had component strips, not minimum reels, so we appreciated the feeder system and could see that other machines didn’t have the same kind of flexibility for smaller volumes.”

The ability to handle a wide range of technologies and board designs was also key to Khushal’s decision. “The Accurex team asked me: ‘Which kinds of PCBs will you be building? And which segment?’ I said: ‘I don’t know – I need to handle all varieties!’ Sure, we knew that quality and accuracy were important, but I didn’t know at the time how complex our products would get.”

Growing throughput

Today, nearly ten years later, Accurex continues to service and support PCB Power’s assembly equipment as it evolves to meet changing customer needs.

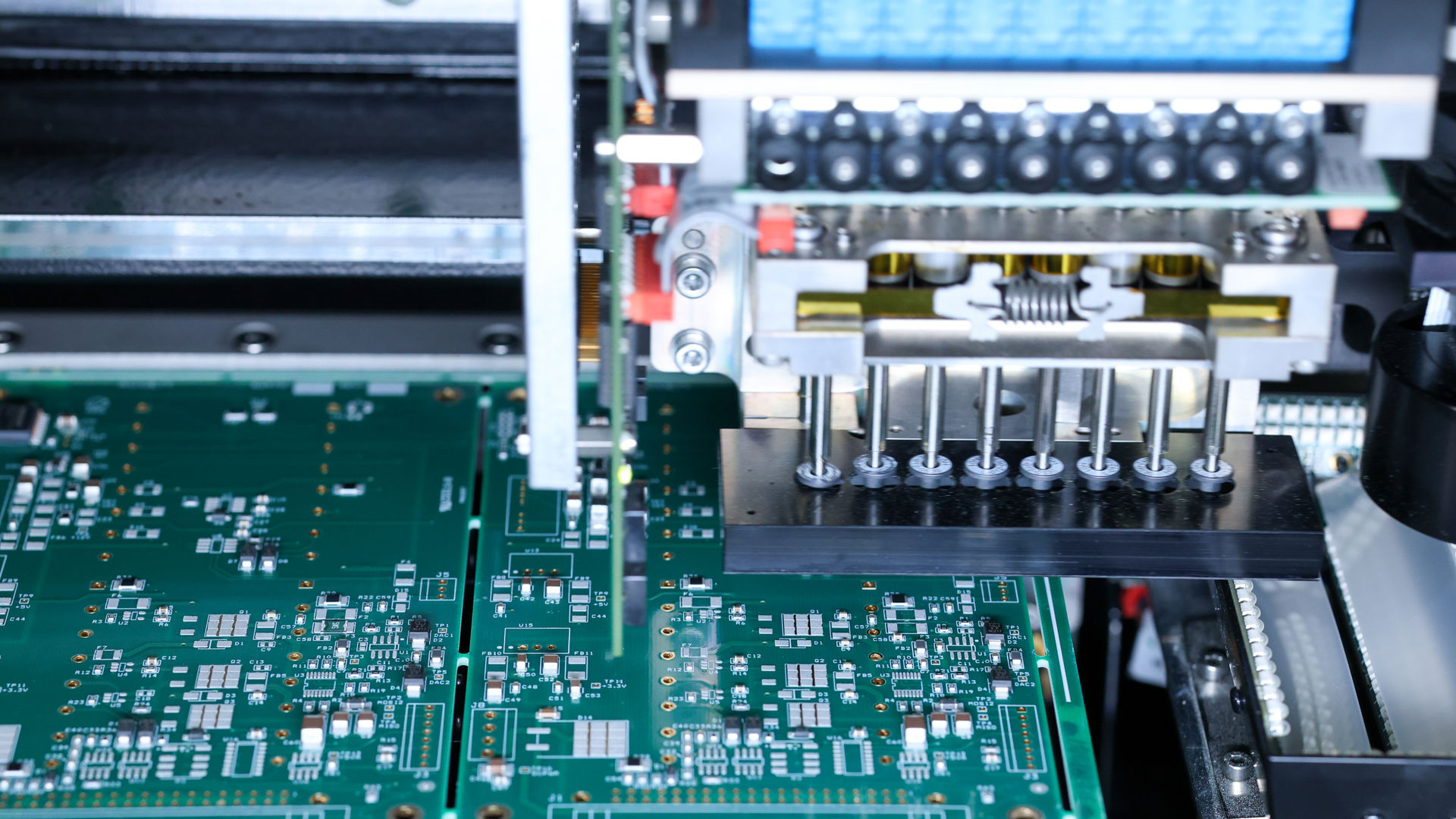

Photo: PCB Power showing shop floor of surface mount technology line (SMT).

“It’s really user-friendly for our team,” says Khushal, “which is one reason we went for a second Mycronic machine – we liked the ease and speed of changeovers.”

Close support

Throughout the period since 2017, PCB Power has increased its overall revenue from its business activities by 40% while significantly expanding its customer base. Part of this success, says Khushal, is the close support he has received from Accurex during the company’s expansion. “From day one, the support from Accurex has been excellent,” he says. “Any company can sell, but service isn’t easy.”

Any company can sell, but service isn’t easy.

Going the extra mile

As an example, Khushal points to a time during the pandemic when the Accurex team responded in a way no one thought possible. “We had an issue, and they drove 45 kilometers to another state to bring spare parts that no one else could get access to. And this was at a time where it was impossible to travel without special documentation! 48 hours later the machine was up and running again. I’m still not sure how they did it.”

“It’s a relationship that goes both ways,” adds Ram Mohan, Chairman, Accurex. “From the beginning we saw a company that was building a brand, which we take seriously. So we’ve kept a small team near PCB Power to ensure zero downtime and to always have replacement part stocks.”

The local presence of a knowledgeable service partner is key to the ongoing relationship, says Khushal. “Our production engineers have direct contact with Accurex around any small questions, and we really appreciate it. Because service engineering isn’t easy. It’s really difficult to keep hold of talented service engineers in any industry here.”

Additionally, as an equipment manufacturer Mycronic intends to enhance its local presence to provide better support to its existing customers and distributors. To fulfill this goal, Mr. Vinu Muthayyan has been appointed as the Country Sales Manager for India. Furthermore, Mycronic's regional headquarters are located in Singapore to offer prompt assistance to national distributors in both India and South-East Asia, through an expert second-line support team

Our production engineers have direct contact with Accurex around any small questions

High-quality products for high-reliability industries

As PCB Power continues to grow, producing around ten different orders per day, some which are Original Equipment Manufacturer (OEM) providing components for another company’s product, Khushal looks forward to continuing to expand the company’s customer base. “Now we have aerospace, railway, industry, automotive – quite a few of which are OEMs. We’re becoming the partner of choice for medical, which is always mid-volume. And a lot of EV customers are also still in heavy development, mostly IPC Class 2 and Class 3.”

To support these producers of high-reliability electronics into the future as volumes increase to 5,000 or more boards per batch, Khushal has ensured that space is prepared on the shop floor for a possible third production line.

No matter how many customers are served or how large production volumes grow, Khushal is convinced that the company will always maintain its single-minded focus on quality and service. This commitment, he says, has always been with them from the start.

“Our managing director is the one always talking about the customer, the quality and the accuracy. He’s the reason we are where we are. That’s always been our philosophy: whatever you do, be the best.”

That’s always been our philosophy: whatever you do, be the best.